New Breakthrough! Meyer Optoeletronic Adds New Momentum to China-Europe "Green" Cooperation!

Meyer Optoeletronic, a global leader in intelligent identification and sorting, has been dedicated to the fields of food safety, healthcare, and renewable resources for over 30 years. With unwavering commitment, it has explored ways to protect life and health, striving to ensure that everyone enjoys a happy life.

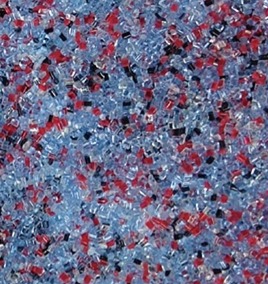

In the renewable resources sector, Meyer Optoeletronic, with its solid technical foundation, has successfully developed a comprehensive waste plastic sorting solution. From color to material, from bottle flakes to whole bottles, from everyday plastic bottles like PET/PE to waste engineering plastics such as ABS/PS, Meyer Optoeletronic remains at the forefront of industry technology, relentlessly pursuing the goal of making all types of recycled plastics as close as possible to virgin plastic in quality, thereby reducing resource waste and environmental pollution.

What’s even more remarkable is that Meyer Optoeletronic has led the industry into a new era of AI unmanned sorting, completely revolutionizing the traditional production model. This has significantly improved the recycling rate of waste plastics, injecting strong Meyer wisdom and momentum into green and sustainable development.

In modern plastic recycling plants, the once busy manual sorting scenes have become history. Now, operators only need to perform simple operations and monitoring at the control console. This is a vivid example of the digital transformation in plastic recycling, a result of the collaborative efforts of leading enterprises and Meyer Optoeletronic.

Recently, Meyer Optoeletronic has achieved another milestone! Its self-developed AI sorting equipment and processes have not only spread across China and achieved large-scale applications, but also successfully introduced this innovative technology into the European market through a strategic partnership with Kingfa Technology, landing in Spain at Kingfa Environmental.

This breakthrough not only fills the gap in complex waste plastic treatment technology for local European enterprises, but also highlights the outstanding innovation capabilities of Chinese companies in the field of green technology.

Meyer Optoeletronic was invited to attend the commissioning ceremony at Kingfa Environmental in Spain.

Kingfa Technology is a leader in the high-performance materials sector, serving over 1,000 renowned companies worldwide. It is expected that Kingfa Environmental in Spain will form an annual production capacity of 30,000 tons of high-performance recycled plastics, committed to using innovative technologies to achieve high-value utilization of waste plastics and address Europe's plastic waste management challenges. It will also provide low-carbon materials for industries such as automotive and electronics, forming a "environmental governance - resource recycling - industrial application" closed loop.

It is particularly noteworthy that, at the critical moment when the EU Carbon Border Adjustment Mechanism (CBAM) is about to be implemented, this project holds strategic significance. It not only establishes an important cooperative bridge for China and Europe to jointly tackle climate change, but also provides a model for international environmental cooperation under the "dual carbon" context.

Meyer’s AI unmanned sorting equipment is running efficiently.

Guests are learning about Meyer’s latest material sorting process.

Looking ahead, Meyer Optoeletronic will continue to deepen industry collaborations, strengthen its global market presence, and drive innovation to become a world-class high-tech company, ensuring that intelligent recognition technology protects the happiness of more people’s lives.